Table of Contents

- Introduction: Why Warehouse Electrical Installation Matters

- Understanding Warehouse Electrical Installation

- Key Considerations for Warehouse Electrical Installation in Melbourne

- Understanding Local Regulations and Codes

- Selecting the Right Industrial Electrician in Melbourne

- Features and Benefits of Professional Warehouse Electrical Installation

- Practical Tips for Preparing Your Warehouse Electrical Installation

- Exploring Technological Upgrades and Innovations

- Long-Term Maintenance and Safety Considerations

- Case Study: A Melbourne Warehouse Upgrade

- Conclusion

Warehouse Electrical Installation Melbourne: Industrial Setup Requirements

For small business owners operating warehouses in Melbourne, ensuring your facility’s electrical system is both robust and compliant is essential. Whether you’re setting up a new facility or upgrading an existing one, understanding the complexities of warehouse electrical installation can be the key to a smooth and efficient operation. In this comprehensive guide, we’ll walk you through everything you need to know—from the basics of electrical design and load requirements to compliance with local codes and selecting the right industrial electrician in Melbourne. Let’s dive in!

—

Introduction: Why Warehouse Electrical Installation Matters

When running a warehouse, your facility is more than just a space for storing goods—it’s a vital component of your business infrastructure. Excellent electrical installations power your lighting, machinery, safety systems, and much more. Poor or outdated electrical systems can lead to costly downtime, safety hazards, and non-compliance with Melbourne’s strict regulations.

The topic of warehouse electrical installation in Melbourne isn’t only about keeping the lights on. It involves a multidisciplinary approach encompassing energy efficiency, safety, and adaptability to modern technology. This blog post is designed to help you understand why a professional electrical setup is crucial for your business, the potential pitfalls to avoid, as well as the features and benefits of partnering with experts who specialise in commercial electrical services in Melbourne.

Whether you’re a small business owner in Melbourne or a facility manager looking for industrial electrical contractors, learning the best practices for warehouse electrical installation can save you time, money, and stress.

—

Understanding Warehouse Electrical Installation

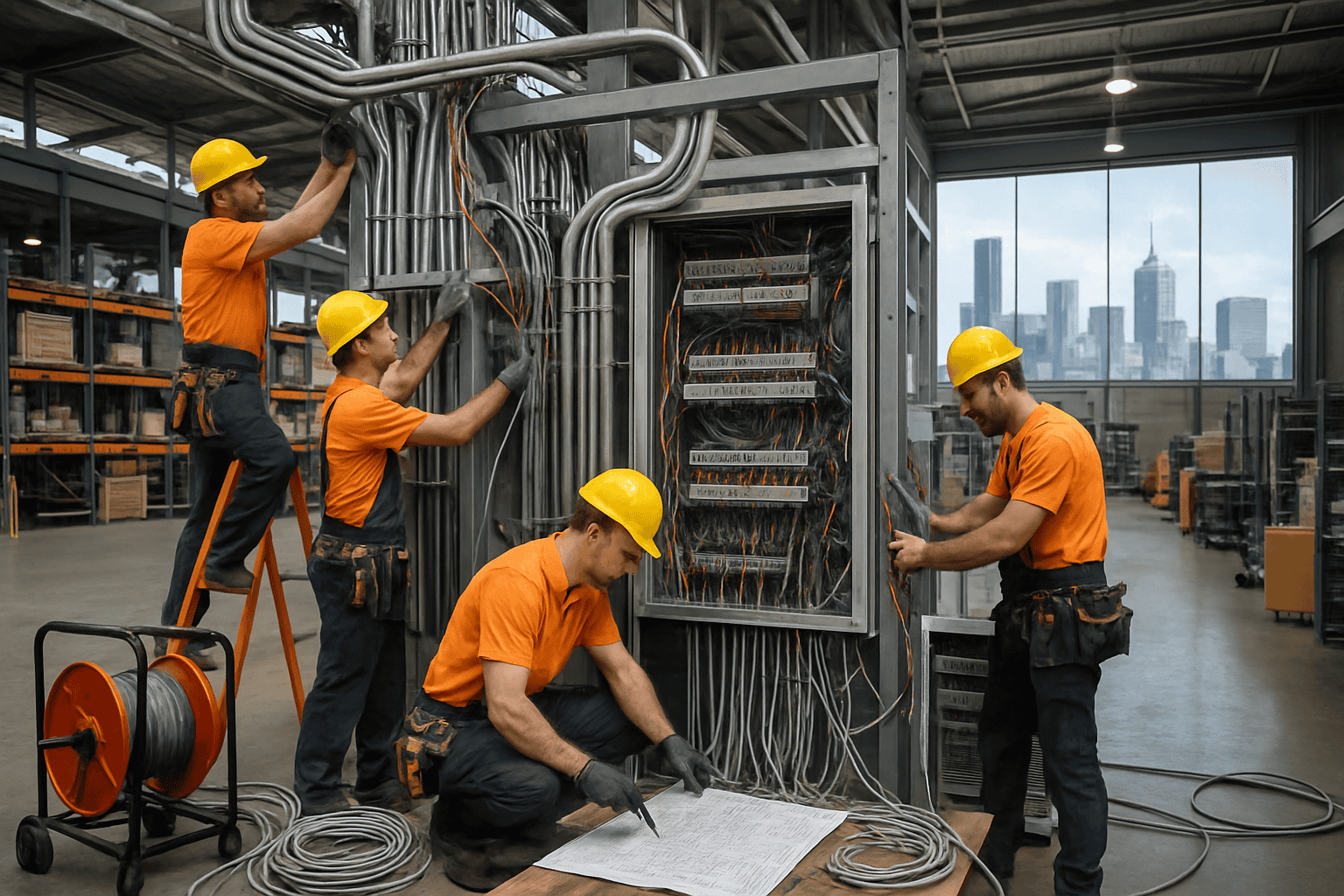

Warehouse electrical installation covers a broad range of systems and processes that are critical to the functioning of industrial and commercial spaces. Here’s what typically falls under this umbrella:

- Electrical Wiring and Conduit Installation: Proper wiring is the backbone of any electrical system. For warehouses, this involves installing heavy-duty cabling and conduits that can handle significant power loads.

- Distribution Board and Panel Installations: Setting up the correct distribution boards and panels ensures that electricity is evenly and safely distributed throughout the facility.

- Three-Phase Power Installation: Many industrial facilities require three-phase power to operate heavy machinery and equipment efficiently.

- Lighting Solutions: This isn’t just about bright lights. It includes high bay lighting installation, LED lighting for warehouses, emergency lighting installation, and energy-efficient solutions.

- Warehouse Security Systems: Integration of security systems such as CCTV, access controls, and alarms, which are all dependent on a reliable electrical supply.

- Data Cabling and Industrial Ethernet: With the rise of warehouse automation, robust data cabling and internet connectivity have become essential.

- Electrical Upgrades and Maintenance: Regular maintenance checks and necessary upgrades keep your system safe and up-to-date with the latest technology and regulatory standards.

Commercial electrical services in Melbourne have evolved to offer tailored solutions that meet these diverse requirements. The goal is to combine functionality with safety, efficiency, and compliance.

—

Key Considerations for Warehouse Electrical Installation in Melbourne

When planning your warehouse’s electrical installation, there are several important factors to keep in mind:

1. Load Requirements and Power Distribution

Every warehouse has unique power demands based on machinery, lighting, HVAC systems, and other electrical appliances. An industrial electrician in Melbourne can help assess your facility’s electrical load requirements warehouse. They will design a system that accommodates both current demands and future expansions. Key considerations include:

- Accurate Load Calculation: Ensure that your system can handle the maximum possible load without overloading circuits.

- Balanced Power Distribution: Prevent short circuits, tripped breakers, and potential fire hazards by having a balanced electrical load.

- Future-proofing: Design your electrical setup for scalability—consider additional outlets, higher capacity panels, and adaptable wiring configurations.

2. Safety Compliance and Electrical Codes

Australia, and specifically the state of Victoria where Melbourne is located, has rigorous safety and electrical codes. Non-compliance isn’t an option—it’s a matter of legal and operational necessity. Critical aspects include:

- Warehouse Electrical Safety Compliance: Adhering to local codes ensures the safety of your employees and premises. This involves regular safety inspections and adherence to guidelines set by regulatory bodies.

- Emergency Lighting Installation: Every warehouse needs a reliable emergency lighting system for evacuation and safe movement during power outages.

- Fire Safety Systems: Electrical designs must integrate with your warehouse’s overall fire safety protocols, including fire alarms, extinguishers, and sprinkler systems.

- Distribution Boards and Switchgear: Ensure that your electrical panels are installed and maintained by licensed professionals to adhere to the Australian standards.

3. Energy Efficiency and Sustainability

Energy efficiency isn’t just good for the environment—it’s also cost-effective. By adopting energy-efficient solutions, you can reduce your long-term operating expenses. Consider these enhancements:

- LED Lighting for Warehouses: LED lighting installations provide brighter, more energy-efficient options compared to traditional lighting.

- Power Factor Correction: For warehouses with heavy machinery, correcting the power factor can lead to significant energy savings.

- Intelligent Control Systems: Modern warehouses often incorporate smart systems that adjust lighting and power distribution based on occupancy and operational demands.

- Industrial Power Installation: Consulting with experts for industrial power installation ensures that you’re integrating eco-friendly and energy-efficient designs from the start.

—

Understanding Local Regulations and Codes

Melbourne, like the rest of Australia, follows specific electrical standards to ensure safety and performance in industrial spaces. When planning your warehouse electrical installation, it’s crucial to understand these local regulations:

Australian Standards and Compliance

- AS/NZS 3000 (The Wiring Rules): This set of standards outlines the minimum requirements for electrical installations in Australia. Any electrical work in your warehouse must adhere to these provisions.

- Victorian Building Regulations: In Melbourne, your installation must also comply with state-specific building and safety regulations. These include providing adequate emergency exits, proper installation of safety systems, and regular electrical inspections.

- WorkSafe Victoria Guidelines: WorkSafe Victoria provides a framework for workplace safety, particularly for commercial and industrial environments. Their guidelines cover risk assessments, equipment safety, and emergency protocols.

Best Practices for Compliance

- Hire Licensed Professionals: Always engage licensed and experienced electrical contractors who are familiar with both national and local codes.

- Regular Inspections: Schedule periodic electrical safety inspections to ensure ongoing compliance.

- Documentation: Maintain thorough documentation of all electrical work. This includes design blueprints, compliance certificates, inspection reports, and maintenance logs.

- Emergency Preparedness: Confirm that all emergency systems (lighting, alarms, etc.) are compliant and well-maintained.

By ensuring that your installation adheres to these codes and standards, you safeguard not only your facility and equipment but also the wellbeing of your employees.

—

Selecting the Right Industrial Electrician in Melbourne

Choosing the right industrial electrician for your warehouse electrical installation can make all the difference. Here are some practical tips to help you find a commercial electrical contractor who meets your needs:

Research and Recommendations

- Online Reviews and Testimonials: Check online platforms and local directories for reviews of commercial electrical services in Melbourne. Websites like WordPress or local business directories can provide insightful feedback from previous clients.

- Ask for Referrals: Reach out to other small business owners or industry associations in Melbourne who have undergone similar installations.

- Check Credentials: Ensure the contractor is fully licensed, insured, and has specific experience in warehouse electrical installations. Look for certifications and memberships in professional bodies.

Evaluating Experience and Expertise

- Relevant Experience: Look for contractors that specialise in industrial, warehouse, or commercial projects. Their familiarity with industrial power installation, electrical wiring for warehouses, and three-phase power installations is vital.

- Portfolio of Past Projects: Ask for a portfolio or case studies of similar installations. This will give you a clear picture of their work quality and the challenges they’ve successfully tackled.

- Local Knowledge: A contractor familiar with Melbourne’s electrical requirements and local regulations can save you from compliance headaches and ensure that your installation meets all necessary standards.

Communication and Project Management

- Transparent Communication: Choose a contractor who communicates clearly about timelines, project scope, and costs right from the start.

- Detailed Quotations: Request detailed quotations that break down labour, materials, and potential contingencies. This transparency helps prevent unforeseen costs.

- Post-Installation Support: Find out if the contractor offers ongoing maintenance and support services. Regular check-ups and prompt troubleshooting are essential for keeping your warehouse’s electrical system in optimal condition.

—

Features and Benefits of Professional Warehouse Electrical Installation

Investing in professional warehouse electrical installation comes with a host of benefits that can significantly support your business operations:

Enhanced Safety

- Compliance with Regulations: Professional installations ensure adherence to all safety codes, reducing the risk of accidents and costly fines.

- Robust Safety Systems: Features like emergency lighting installation and fire safety integration provide vital security during emergencies.

- Prevention of Electrical Faults: Expert assessment and maintenance reduce the risk of electrical faults, which could lead to fires or operational downtime.

Increased Efficiency and Reliability

- Optimised Power Distribution: Professional design ensures your load requirements are met without overloading circuits, thereby enhancing efficiency.

- Modern Lighting Solutions: Upgrading to LED lighting not only improves visibility in high bay areas but also reduces energy consumption.

- Reduced Downtime: Reliable installations mean fewer interruptions to your operations, keeping productivity high.

Financial Savings

- Energy Efficiency: Implementing energy-saving measures like LED lighting and power factor correction can lead to long-term savings on energy bills.

- Reduced Maintenance Costs: Regular inspections and updates by professional electrical contractors minimise the risk of costly repairs in the future.

- Avoidance of Penalties: Compliance with Melbourne’s strict electrical codes helps you avoid fines and possible shutdowns due to non-compliance.

Future-Proofing Your Warehouse

- Scalability: A well-planned electrical system can easily accommodate future expansions or technology integrations.

- Integration with Smart Systems: Modern warehouses often incorporate industrial ethernet installations, data cabling, and automation systems. Professional setup ensures all these components work in harmony.

- Enhanced Property Value: Up-to-date and compliant electrical installations not only boost operational efficiency but also increase your property’s value.

—

Practical Tips for Preparing Your Warehouse Electrical Installation

Getting your warehouse ready for a new or upgraded electrical system involves careful planning and preparation. Here are some step-by-step tips to ensure your installation runs smoothly:

1. Assess Your Current and Future Electrical Needs

- Conduct an Audit: Evaluate your current electrical setup. Identify areas where your existing system is underperforming or potentially unsafe.

- Plan for Growth: Consider how your business might expand. Ensure the design includes additional outlets, higher capacity panels, and possible modifications for future machinery or technology upgrades.

- Load Analysis: Work with an industrial electrician in Melbourne to conduct a detailed load analysis. This will inform the overall design and power distribution strategy.

2. Define Your Objectives and Budget

- Set Clear Goals: Determine what you want to achieve with the new installation—be it improved energy efficiency, better safety compliance, or enhanced operational capacity.

- Budget Planning: Establish a realistic budget that covers all aspects of the project including design, materials, labour, permits, and post-installation maintenance.

- Timeline: Develop a project timeline that minimizes disruptions to warehouse operations. Discuss this timeline with your contractor to ensure their availability and resource planning.

3. Preparing the Warehouse for Installation

- Clear Communication: Inform your employees about the upcoming work, especially if it might affect operations or access to certain areas.

- Safety Protocols: Ensure that the working areas are clearly marked and that proper safety measures are in place during the installation process.

- Space Planning: Make sure that areas for panels, distribution boards, and electrical rooms are unobstructed and easily accessible for inspections and future maintenance.

- Document Existing Infrastructure: Take pictures and create a layout of the current electrical system. This documentation will facilitate any necessary upgrades or modifications by the contractor.

4. Collaborate with Your Contractor

- Regular Updates: Maintain open communication throughout the project, discussing any unexpected challenges or changes in scope.

- Site Visits: Schedule regular site visits with your contractor to ensure that the installation is progressing as per plan and adhering to safety standards.

- Final Inspection: Once the installation is complete, ensure that a thorough final inspection is conducted and that all compliance documentation is in order.

—

Exploring Technological Upgrades and Innovations

In today’s rapidly changing industrial landscape, incorporating the latest technology into your warehouse electrical setup can provide a significant competitive edge. Here are some innovations that are worth considering:

LED Lighting and Energy Efficiency

- High Bay LED Lighting Installation: Modern LED solutions provide brighter illumination, longer lifespan, and lower power consumption compared to traditional incandescent or fluorescent lighting. This leads to a significant reduction in energy costs.

- Adaptive Lighting Controls: Smart lighting systems can automatically adjust brightness based on ambient conditions and occupancy, ensuring that energy is not wasted.

Advanced Data Cabling and Industrial Ethernet

- Seamless Connectivity: With the rise of automation and the Internet of Things (IoT) in warehouses, having a robust data cabling system is essential. It supports seamless communication between machinery, monitoring systems, and cloud-based management platforms.

- Future-Proofing Your Data Needs: As technology evolves, ensuring that your warehouse is equipped with the infrastructure for advanced data and internet connectivity is crucial. This might involve industrial ethernet installation and upgrading your wiring warehouse Melbourne.

Security and Automation Systems

- Integrated Security System Installation: Modern warehouses often integrate CCTV, access control systems, and alarm systems into a single, coherent network. This not only enhances security but also simplifies management.

- Warehouse Automation Electrical Requirements: For warehouses planning to adopt automation, the electrical setup must support robotics, automated storage systems, and other high-tech solutions. Consult with electrical engineers who specialise in industrial spaces to ensure scalability and reliability.

Power Monitoring and Management Systems

- Real-Time Monitoring: Install systems that provide real-time monitoring of your electrical consumption. This helps in identifying areas for further energy optimization and quickly addressing any faults.

- Preventative Maintenance: Leveraging technology to monitor equipment performance can lead to proactive maintenance rather than reactive repairs, reducing downtime and extending the life of your system.

—

Long-Term Maintenance and Safety Considerations

A robust electrical installation is not a one-off project. Ongoing maintenance and periodic inspections are critical for ensuring long-term safety and operational efficiency.

Scheduled Inspections and Maintenance

- Regular Check-Ups: Partner with your industrial electrical contractors in Melbourne to schedule regular inspections. This should include testing of emergency lighting, checking distribution panels, and verifying that all wiring and conduits are secure.

- Preventative Measures: Regular maintenance helps identify any potential issues before they escalate, preventing costly repairs and minimizing risks.

- Documentation and Record Keeping: Maintain a detailed log of all maintenance activities, inspections, and any modifications made over time. This not only helps in planning future upgrades but is also useful for compliance and audit purposes.

Emergency Preparedness and Fault Handling

- Emergency Lighting and Power Backup: Ensure that your warehouse is equipped with robust emergency lighting installation systems and backup power solutions. This is vital for safe evacuation during power outages.

- Fault Finding Procedures: Develop a clear protocol for electrical fault finding within your warehouse. Train your staff to respond appropriately in the event of electrical anomalies.

- Vendor Support: Establish a relationship with a dependable service provider who can offer 24/7 emergency support. Many commercial electrical contractors in Melbourne offer rapid response services to mitigate any interruptions.

—

Case Study: A Melbourne Warehouse Upgrade

To illustrate the benefits and practical application of professional warehouse electrical installation, consider the following scenario:

A local distribution centre in Melbourne faced frequent operational disruptions due to outdated electrical systems. The facility was experiencing frequent tripped breakers, poor lighting in high bay areas, and occasional non-compliance issues during inspections. The centre’s management decided it was time for an overhaul.

The Process

- Initial Assessment: A licensed industrial electrician conducted a comprehensive audit of the existing electrical system. This included a load analysis, identification of non-compliance issues, and evaluation of energy consumption patterns.

- Design and Planning: Based on the audit, a detailed plan was formulated. This plan incorporated a complete revamp of the wiring system, installation of distribution boards that met Melbourne’s safety standards, and an upgrade to LED high bay lighting coupled with smart control systems for energy efficiency.

- Installation: Experienced electrical contractors took over the installation process, ensuring minimal disruption to daily operations. The project included three-phase power installation for heavy machinery, updated emergency lighting installation, and the integration of a centralized security system.

- Post-Installation Inspection and Training: After completion, a final inspection was conducted to ensure full compliance with local regulations, including WorkSafe Victoria guidelines. The staff was also briefed on operational changes and emergency protocols.

The Benefits Realised

- Improved Efficiency: The new system provided balanced power distribution, significantly reducing downtime caused by electrical faults.

- Enhanced Safety and Compliance: With regular safety inspections and adherence to AS/NZS 3000 standards, the warehouse achieved full compliance, eliminating the risk of fines and enhancing employee safety.

- Cost Savings: The upgrade to LED lighting and power factor correction measures led to a noticeable reduction in energy consumption and operational costs.

This case study underscores how professional planning, quality workmanship, and adherence to local regulations can transform your warehouse’s electrical setup into a safe, efficient, and future-ready system.

—

Conclusion

Warehouse electrical installation in Melbourne is a complex, yet critical component of running a successful industrial facility. From ensuring energy efficiency to maintaining rigorous safety standards, every component of your electrical system plays a pivotal role in the day-to-day operations and long-term success of your business.

By working with experienced industrial electricians and commercial electrical contractors who understand the unique requirements of Melbourne’s warehouses, you’re investing in reliability, compliance, and performance. Remember to:

- Assess your current and future power needs.

- Understand and adhere to all local electrical codes and standards.

- Select a contractor with proven expertise and local knowledge.

- Embrace innovative solutions like LED lighting, smart controls, and integrated security systems.

- Schedule regular inspections and maintenance to keep your system operating at its best.

For Melbourne small business owners, this investment is not just about keeping the lights on—it’s about powering your success and enabling your business to grow without interruption. With the right approach and professional guidance, your warehouse electrical installation can become a key asset, driving efficiency, safety, and operational excellence.

If you’re planning a warehouse electrical fitout in Melbourne or need upgrades to your current system, don’t hesitate to get in touch with an industrial electrician in Melbourne today. They can provide tailored advice and reliable solutions that meet all your warehouse electrical requirements, ensuring that your setup is safe, efficient, and compliant.

Remember, a well-designed electrical system is the backbone of a productive, safe, and future-ready warehouse. Now is the perfect time to review your facility’s electrical needs and partner with professionals who can help you create a winning setup. With careful planning, adherence to local regulations, and a commitment to energy efficiency, your warehouse will be perfectly equipped to meet the challenges of today and the opportunities of tomorrow.

By taking these steps, you’re not just installing electrical systems—you’re investing in the longevity and success of your business in Melbourne’s competitive industrial landscape. Let professional expertise guide you through the process, and watch as your warehouse transforms into a safe, efficient, and modern hub for your operations.

Now, let’s get started on powering your growth!

0 Comments